New state of the art Chemotherapy Unit at Ulster Hospital opens in Northern Ireland

The new state-of-the-art Chemotherapy ward has recently opened inside Ulster Hospital in Belfast, Ireland. The new ward is part of a wider £261 Million investment into the redevelopment of Ulster Hospital. Frenger® were selected to design, manufacture, and supply the new unit with their Eco™ Healthcare Active Chilled Beams as well as their Modula Radiant Heating Panels.

The development of the new chemotherapy and cancer ward is part of a joint partnership between Macmillan Cancer Support and the South Eastern Health and Social Care Trust. The opening of the new ward will provide better access to Cancer treatment for the local area.

The new Chemotherapy ward will also house a Macmillan information and support centre helping to further provide better care through the use of the latest Chemotherapy and support services. This new support and information centre is housed on the second level of the development.

The unit itself is a major redevelopment of an existing 1960s building, helping to reduce the environmental impacts of having the ward built as a new building. This not only makes the project more sustainable, but it also still allows the developers to create a striking new facility for the chemotherapy unit at Ulster Hospital.

The new roof extension on level 2 houses the chemotherapy treatment area providing a purpose-built quality environment, which benefits from good daylight provision and pleasant views out over the surrounding landscape terraces and countryside. The roof areas also provide a relaxing, therapeutic environment for patients, visitors, and staff.

Macmillan provided over £2.5 million of the £3 million initial investment for the new unit to be built, which will include assessment and treatment areas, a satellite pharmacy, and the previously mentioned Macmillan information and support centre.

Eco™ Healthcare Active Chilled Beam

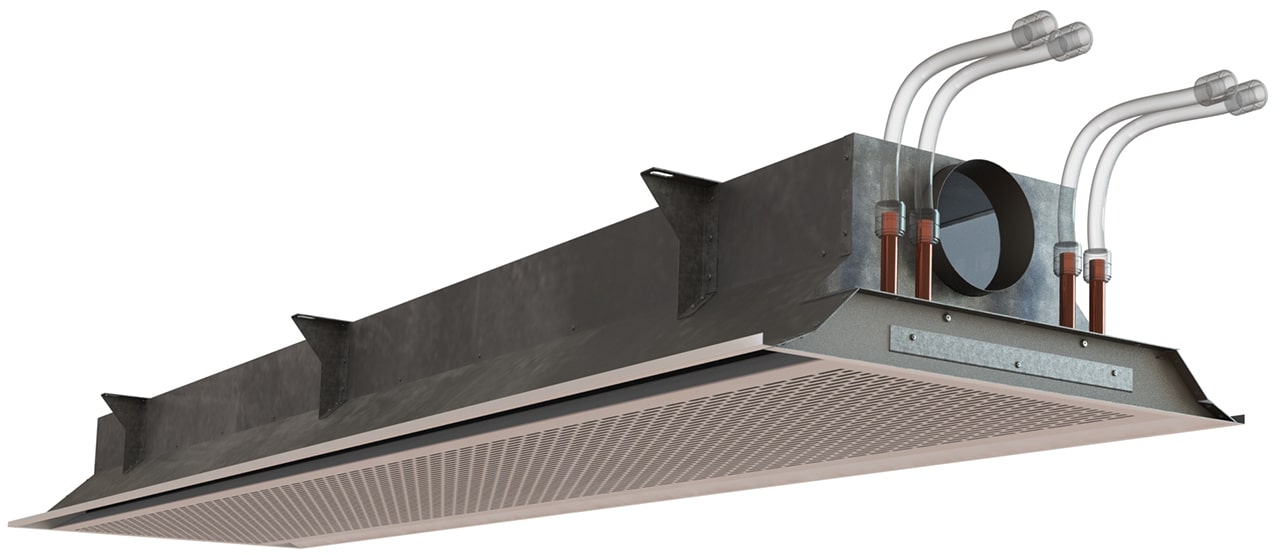

Frenger's® energy efficient and low noise Eco™ Healthcare Active Chilled Beams are designed specifically for healthcare applications. Due to the closed case/back design of the Eco Healthcare Active Chilled Beam, the filtered fresh air and the recirculated air distributed does not come into contact with the 'dirty' ceiling void air and does not re-use any extracted air. This ensures that cross contamination does not occur, providing cleaner air than other HVAC systems.

The conditioned air from the Eco Healthcare Active Chilled Beam is evenly distributed along the length of the unit for optimised heat exchange and energy efficiencies and uniformly spread throughout the space in a controlled and consistent manner thanks to Frenger's AMDV (Air Management Discharge Vanes) and Coanda effect to entrain the conditioned air against the ceiling to ensure optimal thermal comfort levels and indoor air quality. Our Eco™ healthcare beams are supplied as standard with a number of key healthcare features including a 'drop down' heat exchanger that can easily be inspected and cleaned from within the room (no need to access the ceiling void), with all 4 sides of the heat exchanger being fully accessible for easy cleaning and low maintenance.

With high ambient noise levels in patient rooms believed to have negative impacts upon patients and their health and wellbeing. These impacts can range from a lack of sleep, elevated blood pressure or extended recovery times. The Eco™ healthcare chilled beam contributes virtually no detectable noise to occupied spaces, with sound levels recorded under 25dB.

The development of these quiet operation beams have come as a result of significant investment into testing facilities with the UK head office having extensive in-house testing facilities including 3x Climatic testing laboratories, 2x Lighting laboratories and an Acoustic laboratory.

Modula Radiant Heating Panel

Frenger® also supplied their ceiling integrated Modula radiant heating panels to provide comfortable, affordable, and energy efficient heating. Our Modula range, which are supplied in both 'SP' (standard performance) and 'HP' (high performance)options, provide an unobtrusive modular heating panel.

The panel is constructed from smooth-faced Zintec with extruded aluminium heat exchanger pipe seats are fully bonded. Copper heat coils are inserted into the pipe seats for excellent heat transfer characteristics. The 15mm copper coils are produced in-house on Frenger's Full CNC Serpentine Bend Machine from thousand metre drums of copper to make the heating coils without any joints what so ever and to safeguard against the risks of leakage.

All panels are insulated with class 'O' foil 'wrapped' mineral wool insulation pads of 45kg/m³ density. The technology employed in the construction of Frenger's radiant heating panels result in very high heating capacity, all of which are designed, developed, and tested in Frenger's previously mentioned Climatic Test Laboratories and are also Independently Tested and Certified to EN13047.

You can learn more about the products Frenger® has to offer by visiting our products page or read more articles about the international projects Frenger® has supplied on our latest news page. Alternatively, you can contact our office on 61 2 9006 1147 or sales@frenger.com.au.